Silicon Oxycarbide as a Host Matrix of Choice to Stabilize Li-Ion Storage in Nanosized Alloying Elements

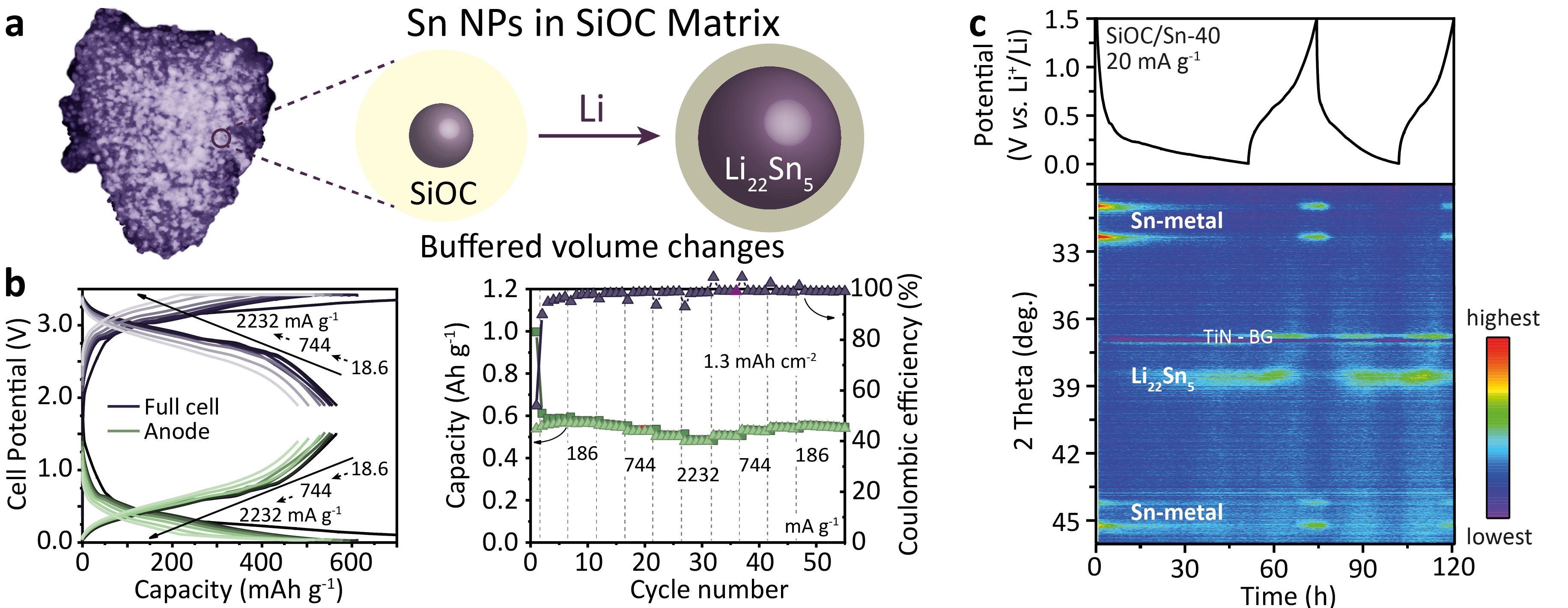

The ever-increased demand in energy has led to a high necessity for innovative energy storage systems[1,2,3] with high energy densities, such as Li-ion batteries (LiBs). To maximize the anodic charge storage capacity of LiBs, alloying-type anode materials such as Sn and Sb have attracted considerable interest because of their high theoretical capacity of 992 and 660 mAh g−1 and a suitable lithiation/delithiation voltage window of 0.01–1.5 V vs. Li+/Li. Recent advances in nanostructuring of the alloying-type anodes provide an effective way of mitigating the challenges of their volume expansion upon lithiation that severely hinder the cycling stability.[4] Besides, one of the prevailing approaches toward stabilization of such electrodes is the embedding of Sn or Sb in the form of nanoparticles (NPs) in a matrix. The matrix helps to buffer the volume changes, impart better electronic connectivity, and prevent particle aggregation upon lithiation/delithiation. In this context, polymer‐derived ceramics, namely, silicon oxycarbide (SiOC), is an appealing candidate for stabilizing Sn and Sb inclusions. This matrix features a high Li‐ion storage capacity ranging from 600 to 700 mAh g−1, low volume expansion upon lithiation of about 7%, and high electronic conductivity. In this study, we report a facile synthesis of Sn[5] and Sb[6] NPs embedded in a SiOC matrix via the pyrolysis of a cross-linked preceramic polymer. The NPs are formed in-situ via a carbothermal reduction during the pyrolysis. We determined that a key element to obtain a homogeneous distribution of NPs in SiOC is the employment of precursors with compatible polarities, allowing for an intimate blending of the functionalized polysiloxanes with the Sn or Sb precursors. This approach proved to be effective for buffering volume changes while retaining practical energy densities and high rate capabilities. For instance, SiOC/Sn nanocomposite exhibited a high rate capability, delivering a high capacity of 553 mAh g‐1 at a current density of 2232 mA g‐1 (≈ 6C for a graphite anode). Additionally, the electrochemical performance of SiOC was assessed in full cell configuration using areal capacities of 1.3 mAh cm-2 being relevant for high-power industrial applications. The mechanism of Sn lithiation in SiOC was evaluated by in-situ powder X-ray diffraction.

[1] R. Dubey et al. ACS Applied Mater. Interfaces 2019, 11, 17686.

[2] K. Kravchyk, R. Dubey et al. Sci. Rep. 2019, 9, 1-8.

[3] R. Dubey, et al. ACS Applied Mater. Interfaces 2019, 11, 39902.

[4] M. Nasir, et al. Adv. Energy Mater. 2016, 6, 1600374.

[5] R. Dubey, et al. Adv. Sci. 2019, 6, 1901220.

[6] R. Dubey et al. 2020, in revision.